Idling engines waste fuel, with a large diesel engine wasting up to one gallon of fuel for each hour it is left idling. Idling also reduces the engine life and the time between maintenance as well as contributing to air pollution.

Unnecessary idling can occur when vehicles wait for extended periods during loading and unloading of materials or supplies or when equipment is not being used.

An idling engine does not generate enough heat to achieve proper combustion. Soot or 'black carbon' deposits can build up on the piston and cylinder walls, contaminating the oil and creating friction that increases the wear on engine components. Limiting idling will also lead to a reduced maintenance as reduced wear will require less frequent oil changes and engine rebuilds and therefore lower the operating costs.

Often modern non-road mobile machinery (NRMM) has an idling management system built in that allows for either mechanical or electrical shutdown of engines after they have been idling for a preset period of time. Operators should check with the manufacturer for specific equipment information and that these idling reduction control features have been enabled.

Fleet managers can plan ahead to efficiently manage the work flow within a project to prevent idling vehicles whilst waiting for deliveries and maximise equipment use across the site.

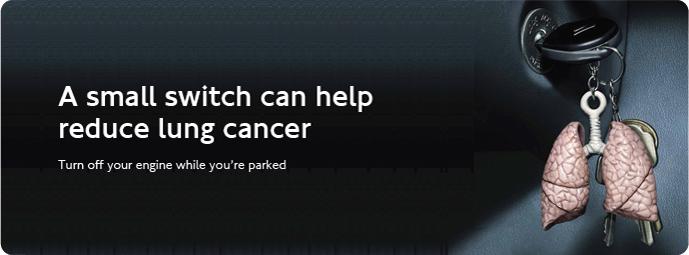

A low cost solution to idling can simply be through behaviour change and raising awareness amongst operators that most modern equipment does not require warm-up or cool-down periods and of the cost implications to the company of idling will encourage equipment operators to assist by switching off their engines when not in use. The long-term health benefits of reducing personal exposure to engine emissions should also be a driver for change.

The Fleet Operator Recognition Scheme (FORS) offer training and support for on-site anti-idling campaigns.

Measuring performance and tracking fuel consumption can be a good indicator of the success of idle reduction policies; although this may have administrative costs there is software available to collect this information. Posting these results can allow operators to see how they compare to others and help encourage a 'switch it off' culture.

The engine on some NRMM also runs additional cab services such as heating and air conditioning as well as powering other functions such as lifting etc. It is possible to use an auxiliary power unit (APU) to supply this power requirement rather than running the main engine.